Our Solutions

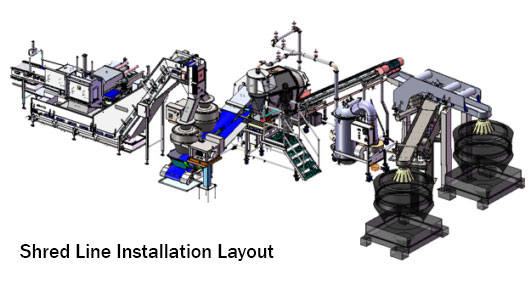

Cheese Shredding & Cutting Solutions

With more than 600 complete systems worldwide, MSI has developed a more effective & efficient way of shredding & cutting of cheese.

The equipment is built to the highest hygiene standards (USDA 3A Dairy Code) for the Food Industry.

All aspects of secondary processing of cheese is within MSI capabilities including Slice, Snack Cutting, Shredding and Portioning.

Washing and Sanitizing

IWM has developed a full line of washing and sanitizing equipment to make clean-up as easy and efficient as possible.

The range includes Pallet Washers, Tote / Bin Washers, Tray Washers, Rack Washers, Sanitizing Tunnel, Cabinet Utensil Washers and Scale Bucket Washers.

Chilling & Freezing Systems

Our spiral freezers and coolers are tailored to customer’s specific requirements. Our focus on details ensures the spiral freezer/cooler is optimized for all applications, from raw dough to fully cooked, ready-to-eat meat and poultry products.

Our range of Individual Quick Freeze (IQF) tunnels implement various product separation and fluidization technologies to ensure careful handling of food products. For sticky products like diced/sliced fruits and vegetables, our acetal plastic conveyor belt solution ensures product release and separation.

We offer a range of innovative technologies for maximizing performance and ensuring the highest hygienic standards, all integral aspects to lowering total cost of ownership.

Automated Vacuum Transfer Systems

Automated vacuum transfer systems including bulk, rip & tip stations & vacuum conveyors.

Vacuum conveyors are generally used to transport bulk materials. As a general rule, the term “bulk materials” usually refers to powder and granules, wherein – up to a certain particle size – tablets, pills, capsules, flakes, pellets and even larger pieces are conveyed.

Through the use of special vacuum generators which can achieve a high vacuum level, it is also possible to transport liquids and viscous media.

Volkmann vacuum conveyors are constructed in a modular fashion and as a result, they can be adapted to individual conveying task so that almost all types of bulk materials can be conveyed.

Installation & Training Services

PT Associates carries out complete installation including the mechanical & electrical work in conjunction with our customers.

All work is done in accordance with OH&S regulations and Australian / New Zealand standards.

Then full hands on operator / maintenance training is carried out including full documentation.

Consultancy

PT Associates are able to provide customers an independent assessment of either existing plant or future plant upgrade.

These assessments incorporate: